| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | ONESEINE |

| Certification : | ISO9001,ISO14001 |

| Model Number : | ONE-102 |

| Price : | USD0.1-1000 |

| Delivery Time : | 5-8 working days |

| Payment Terms : | T/T, Western Union |

| Supply Ability : | 1000000000pcs/mon |

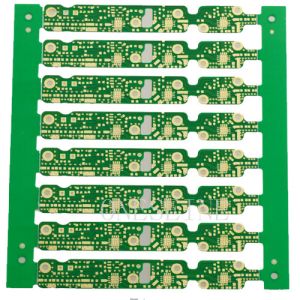

Single Sided roger 4003c material PCB Fabrication

Quick detail:

Layer | 1 | Material | Rogers 4003 |

Solder mask | green | Thickness | 0.254MM |

Surface | Gold plating | Copper weight | 1OZ |

Silkscreen | white | Size | 32*40CM |

Single Sided PCB information:

Single-sided PCB(Single-sided printed circuit board) is the simplest printed circuit board, these boards don't require plated through holes and only have a circuit pattern on one side.These single sided PCB are widely used in various electronics applications.

Single sided pcb is the basic simple PCB, parts is layout on one side and the circuit is on the other side. As there is only layer conductor, it is called single sided pcb (Single-sided pcb or one layer pcb. It is restricted in the circuit design (because there is only one side conductor, and no cross permitted, each line must have its own path), so it is more frequently used in the early printed circuits pcb.

Single sided PCB diagram mainly use network printing (Screen Printing) .That is to print resist on the bare copper, etch and then print solder mask, finally punching to finish parts plated hole and profile. In addition, some small amount of various products usually use photoresist to pattern circuit.

RT/duriod

Rogers RT/duroid® high-frequency circuit materials are filled PTFE

(irregular glass or ceramic) composite coversfor use in high

reliability, aviation and defense applications. The RT/duroid types

have a long industry nearness of providing high-reliability

materials with predominant performance. This kind of material has

several benefits:

1 Low electrical loss,

2. Low moisture absorption,

3. Stable dielectric constant (Dk) over a wide frequency range, and

4. Low outgassing for space applications.

RO3000

RO3000 laminates are ceramic filled PTFE composites intended for

use in the commercial microwave and RF applications. R03000 series

laminates are circuit materials with very consistent mechanical

properties regardless of the dielectric constant selected. Due to

this characteristic, when designing multi-layer boards with varying

dielectric constants, there will be very little issues if any at

all The dielectric constant VS temperature of RO3000 series

materials is very stable. RO3000 laminates also are available in a

wide range of dielectric constants (3.0 to 10.2). The most common

applications are:

1. Surface mount RF components,

2.GPS antennas, and

3. Power amplifiers.

RO4000

RO4000 laminates and pre-pregs possess favorable properties that

are highly useful in microwave circuits and instances where

controlled impedance is needed. This series of laminates are very

price optimized and are also fabricated using standard FR4

processes which makes it suitable for multi-layer PCBs.

Additionally, it can be processed lead-free. The series of RO4000

laminates offer a range of dielectric constants (2.55-6.15) and are

available with UL 94 V-0 flame retardant versions. The most popular

applications of this are:

1. RFID chips,

2. Power amplifiers,

3. Automotive radars, and

4. Sensors.

TMM®

Rogers TMM® thermoset microwave laminates fuse dielectric constant

uniformity, low thermal coefficient of dielectric constant (Dk),

and a copper matched coefficient of thermal expansion. Because of

their electrical and mechanical stability, TMM high-frequency

laminates are perfect for high-reliability strip-line and

micro-strip applications. This kind of material has several

benefits:

1. Wide range of dielectric constants (Dks),

2.Excellent mechanical properties, cold flow, and resists creep,

3. Exceptionally low thermal coefficient of Dk,

4. Coefficient of thermal expansion fit to copper taking into

account high reliability of plated through-holes,

5. Available copper clad in larger formats, allowing the use of

standard PCB subtractive processes,

6. No wreck to materials during fabrication and assembly processes,

Resistant to process chemicals,

7. Thermoset resin for reliable wire bonding,

8. No specialized production techniques required,

9. TMM 10 and 10i laminates can replace alumina substrates, and

10. RoHS compliant, environmentally friendly.Below is a table that

shows the characteristics of various types of PCB materials.

|